UV Light Measurement

The next major area to be considered in the UV light journey is actually measuring the quality and quantity of the UV light source output. As you probably have experienced in 3d printing, if your exposure is too little (measured in mj/cm2), the result is loss of time and scrapped materials. The converse is also true with over exposure, lost time and materials. Once the process’ “window” parameters are determined, care should be taken to stay within the “window’s” parameters. One can obtain more material but not time lost.

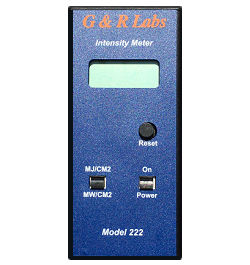

This is where a correct and accurate UV light meter (radiometer) is absolutely required. There are a lot of UV light meters available in the marketplace; however, very few are accurate and reliable. The real questions are do these UV meters accurately measure what the photopolymer reacts to and do these measurements hold up over time and through use?

We might know UV light falls into several categories: UV A, UV B and UV C. We also might know when one measures UV light intensity it is measured in milliwatts/centimeters squared (mw /cm2). Millijoules/centimeter square measures energy or total dosage (intensity x time = energy (i x t=e). Time is measured in seconds. If the intensity is too low, the correct photopolymer reaction will not occur. If the energy is insufficient, again, the photopolymer doesn’t properly react. However, beyond that how much do we really know? How do I know my mw/cm2 or mj.cm2 measurements are providing an accurate and repeatable measurements or just some relevant number? Let’s first discuss accuracy, then reliability.

UV Light Meters

The two main functions of a UV light meter are to measure intensity and energy. Without these two measurements we only have unknowns. Intensity is measured in mw/cm2 to a given wavelength response. The probe you use to measure intensity consist of several components. If these components are correctly designed and selected, the probe will send the correct signal to the meter and you will have taken the correct measurement. However, not all UV meters use the same components to measure intensity and energy, therein lies the problem.

One key factor in taking accurate and repeatable measurements starts with complying with a stringent standard. Worldwide the most accepted and stringent standard is the National Institute Standards and Technology (NIST) developed and used in the United States. If the measurement doesn’t meet the NIST standard, then it is just a relative number to an unknown standard and this creates a significant problem. Every UV light meter needs to be periodically calibrated. One of the most frequent question, George Richardson, is asked “why am I getting different measurement readings since my UV meter has been calibrated.”

His response is to ask a question, “When you bought your meter what standard was used?” Worldwide some UV light meter manufactures may use in house values and some manufactures just rely on whatever reading that current meter provides. Mr. Richardson states, all of our UV light meters are initially calibrated to a published specification of ≤ 3% of the NIST standard; however our in-house specification is ≤ 1% of the NIST standard. Furthermore, all of the meters sent to us for “re-calibration” are calibrated to the NIST standard. The NIST standard is a known standard and is used “year in and year out.”

The second most key factor in taking accurate and repeatable measurements are in the designed and the individual components specifications selected to insure repeatability. The design must insure the various components work together, eliminate possible sensor

degradation, and exclude moisture potential. The design also takes into account the cost to manufacture to tighter specifications. These specifications include thickness, type of materials, supplier consistency of material, etc. An accurate probe will measure what the photopolymer resin reacts to and be repeatable long term if these components are carefully incorporated. This selectivity insures the UV light meter will comply to the NIST standards, as mentioned above, but is more costly and necessary to safeguard longevity and integrity for the end users. This attention to quality control achieves insurance that calibration accuracy is repeatable and consistent from calibration to calibration, probe to probe, and from meter to meter.

1. George Richardson is founder of G&R Labs in 1996 and co-founder of Optical Associates (OAI) in 1974. Mr. Richardson dedication in developing UV light meters to measure accurately and reliably to NIST standards and calibrate to NIST standards provides users assurance their measurements are traceable and accurate.